The instrument for laser inspection of tubes, bars and small diameter barrels straightness

Home → Optical non-contact measurement systems → The instrument for laser inspection of tubes, bars and small diameter barrels straightness

It may be interesting for you:

PROBIUS UNO - Laser control equipment for the inside diameter and straightness of pipes

For diameters from 45 mm.

PROBIUS UNO...

PROBIUS ULTIMATE - Complete Pipe Measurement and Inspection System

For diameters from 90 mm.

PROBIUS ULTIMATE...

LASERSCAN Precise measurement of the outer diameter and roundness

A device for precise control of the outer...

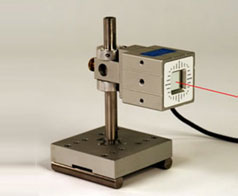

Device for laser control of straight pipe, rods and the like small diameters

Laser control device is designed to control the pipes with an inner diameter of 7.5 mm.

The device consists of:

Measuring principle

The measured item is fixed in the prisms. In automatic mode, the stock, mounted on the carriage, moves along the item. A tripod-type centering device, in the centre of which a laser axis generating module is rigidly fixed, is fastened to the end of the stock through the precision propeller shaft. The module with laser from the centering device is mechanically decoupled from the stock and by its position repeats the inner profile of the measured items.

The laser beam projected onto the receiver at each point in time provides information about the deviation of the axis by internal diameter of the item based on equal length of the centering device (~ 30 mm). A specialized software calculates the straightness of the item: along the entire length, at a certain control area, and generates a graph - the dependence of the deviation from the axis along the length of the item, when scanning the item along the length or along the array of instantaneous measurements.

Laser module with an optical system forms a parallel beam of light, structured for the several circles inscribed in each other. The receiver receives the image of these circles on the CCD matrix and defines the center of the laser line on the set of points. The use of circles, rather than the usual laser line, eliminates a number of uncertainties associated with the possible misalignment of the elements of the measuring system and enables the subpixel image processing with increased accuracy.

Technical and metrological characteristics